Cold Kiln Alignment

Kiln should be aligned; deformation and distortion of kiln shell are minimized so that loads on support bearings properly shared. Deformation and distortion of kiln shell highly increases mechanical wear and tear, poor load sharing on support roller its reason roller and bearing problems.

Alignment means positioning the support rollers so that flexing of kiln shell is minimized, initial point is to know how the rollers holding the kiln with respect to straight line. Our basic sequences are to align the support rollers with the centerline of the kiln in accordance with overall slope of the kiln. This ensures that entire load of the kiln is distributed equally across all component.

Indications of Kiln out of alignment

- Wear after tire roller surface which is recently repaired

- Chattering /Vibration noises

- Excessive damage in Girth gear and pinion

- Excessive wear on tire and support roller

Alignment check points

- Shut down kiln and collects initial data

- Position a laser tracking unite at various position

- Record measurement of various position diameter ,face ,profile of girth gear /pinion ,Tire and rollers ,kiln shell

Result Analysis

- Our engineer analyzes all results of measurements

- Software program visualize kiln and corresponding measurements, on behalf of that conclude adjustment of support roller

Roller Adjustment

- Shimming; insert shim under bearing housing in order to adjust elevation of support roller.

- Skewing ; move bearing housing in /out in order to align the support roller with the centerline of the kiln

- Sometimes we use both shimming and skewing

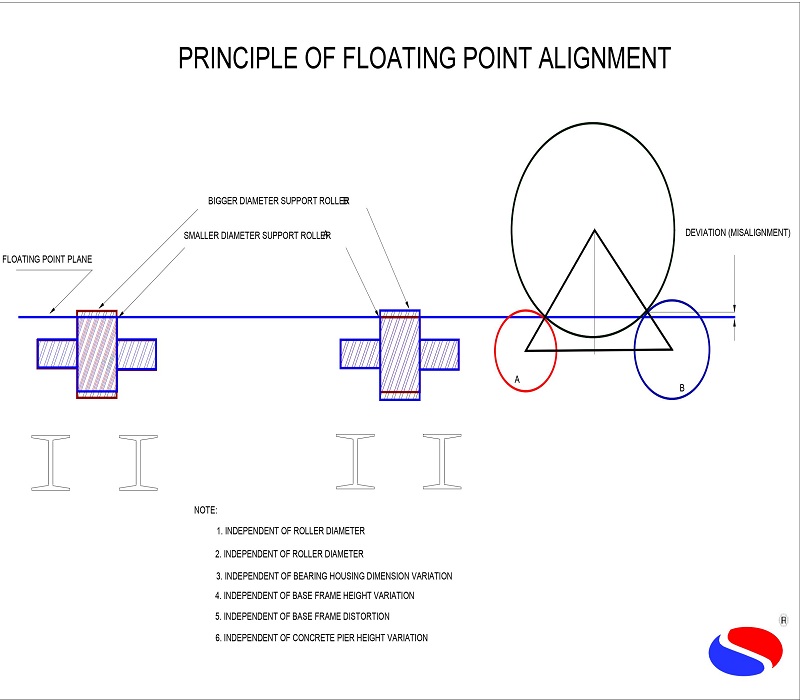

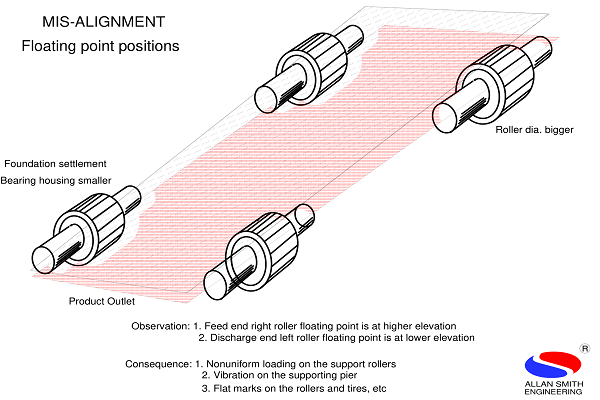

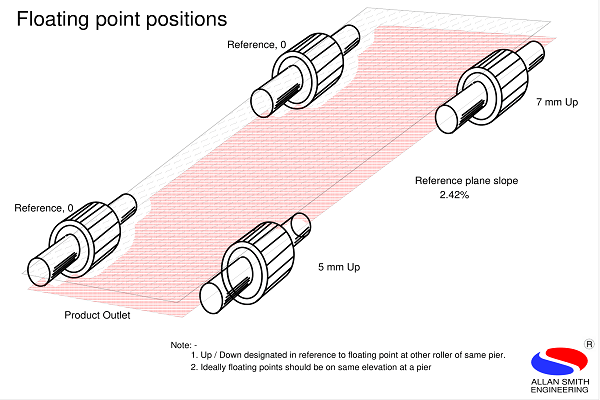

Float Point Position

Point of contact of Tyre & rollers. The point various or float upon the change in support roller diameter on the position. The ideal points of all the four rollers positions should fall on a plan. And the change in the difference in the point on vibration. However, if points are not in a plan it results in vibration in hot bearing & starts of mechanical problem in the kiln.

Floating Point Plane (FPP) Alignment

FPP alignment is specially designed for 2 pier kilns, to take advantage of measurement- during Cold conditions

- during Hot conditions

Proper alignment of a machine is mandatory for reliable operation, is a starting point for any mechanical maintenance program in a rotary kiln, it includes all mechanical characteristics of the kiln and components. Initially, we study the geometrical status of kiln Tyre/support roller, support system, analyse the axis of rotation.

After collection of all required data and the analysis, we conclude the floating points on every support station and the corrections. The floating-point method is designed to bring a point on the reference plane to accomplish uniform load sharing with all support rollers

Benefits

- Measurement and correction during the cold condition

- Some corrections demand the axis corrections by the installation of shims.

- Measurement and correction during kiln in normal operation

- Some corrections demand the axis corrections by movement in H direction.

- Above corrections ensures, working whole system working together, instead of against each other.

Our service team targets to reduce operating costs and increase the wear life of various components. The alignment corrections help various kiln design, speed, process, products, and completion of work within the time frame. Our focus is to carry out RCA of the problem observed in the kiln to conclude and implement with suitable corrections

Report

We provide detailed report of alignment with sequence of correction also beneficial in view of predictive maintenance.

Advantages of ASEPL cold alignment:-- Helpful in periodic/Annual/shutdown / Predictive maintenance

- Unmatchable quality and accuracy level

- Study of kiln integrating all connecting system

- ASEPL team expertise verity of health check of kiln as under.

- Shell ovality check

- Coupling and shaft alignment

- Seal inspection

- Various troubleshooting

Principle Of Floating Point Alignment