Kiln Shell And Chair Pad Replacement

Recently carried out welded chair pad replacement. Upon removal of the pads observed shell is severely constricted at the middle of chair pads, in excess of 10 mm. The damage caused difficulty in measurement and conclusion for the expected shim thickness to ensure the tyre operation with reasonable migration.

Also upon the tyre measurement, the outer diameter observed reduced by 30.2 mm, and that the inner diameter, increased by 8.4 mm.

As OEM supplied welded chair pads and upon considering the operation, concluded to retain the OEM design and opted to install the welded chair pads. But the shell constriction could poise the problem of repeated weld crack, upon the weld using conventional methods.

Tyre side face is worn out in excess of 12 mm on one side and in excess of 8 mm on another side. The wear imposes difficulty to install standard tyre retainers and if opted for higher dimension will hit guide roller at the pier.

In view of the above constraints, the proper methodology was adopted with an aim for following:- Proper alignment of tyre within 0.5 mm during operation, so as to minimize load on tyre retainers.

- Ensure the longevity of the chair pad weld.

- Around 10 mm tyre migration during normal operation.

- Tyre operates with light loading on retainer and an almost uniform gap between tyre retainers on another side.

- Chairpad is almost matching to the shell completely throughout the length.

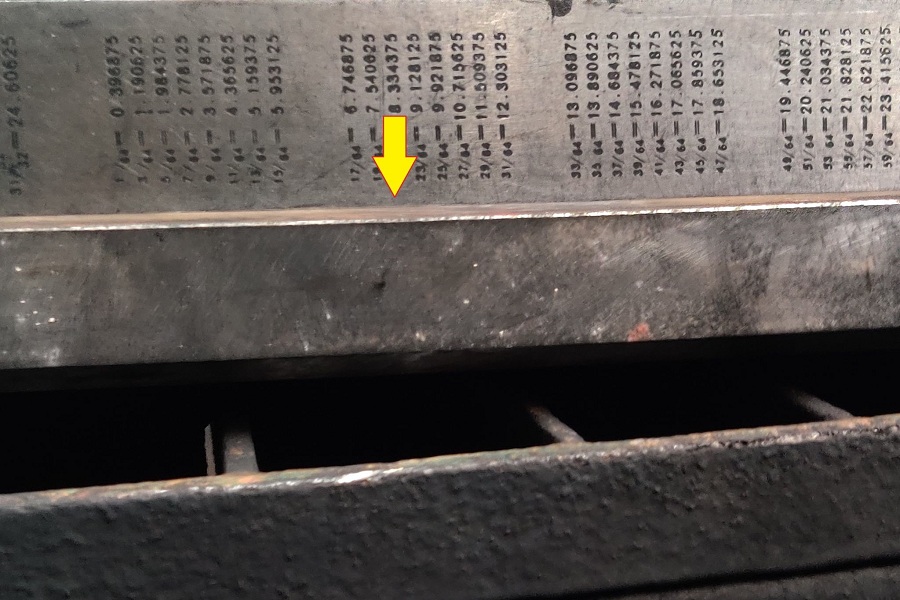

- Tyre migration observed 9-10 mm / rev. (shim installed of thickness 10 mm after rolling plate to the required radius.)